The Cartridge type selected, and how the adhesive is filled into it, are often key to optimal shelf-life and a good end-user experience.

2-Component Adhesives are typically specialty products; with many formulations and formulation variants to suit different applications.

Therefore 2-Component cartridges are mostly filled in smaller quantities than 1-Component Cartridges, and often suit Semi-automatic Filling Equipment, with only the higher-demand products justifying Fully automated Filling Equipment.

However, with Grunfeld ‘Vario’ Automated Filling Systems combinations of similar products or cartridge sizes, can be filled on the same filling system – making a Fully-automated system cost-effective, where it may have been cost prohibitive before.

Likewise, with Grunfeld ‘Vario’ Semi-automatic Systems; various cartridge sizes can be filled from the same filling system. Often the end-users are tooling up with applicator guns to fit a certain cartridge size, so the ability to fill different cartridge types can be an advantage.

When specifying a 2-Componet Cartridge Filling System some of the key considerations are; the output required (pieces per minute/hour), the ratio(s), the viscosity of the product to be filled, and the chemistry of the product to be filled.

Chemical compatibility between the fluid contact (wettable) parts of the filling system and the product to be filled is very important, because compatibility issues can lead to premature wear in the parts of the equipment (typically the wearing parts/seals) or could lead to contamination of the product being filled. As 2-Components products are typically quite chemically reactive by their very nature, compatibility is an important factor.

Showing all 6 results

-

2-COMPONENT FIXED SEMI-AUTOMATIC CARTRIDGE FILLING

View More -

2-Component Vario Semi-Automatic Cartridge Filling

View More -

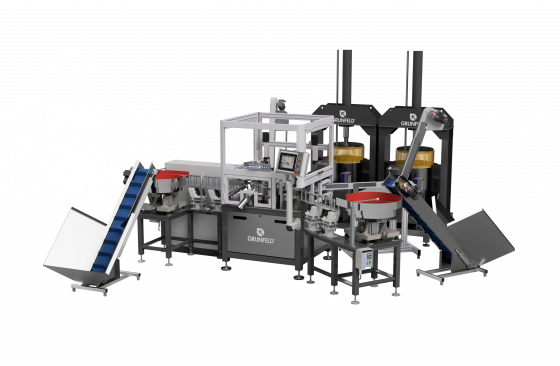

AUTOMATED 2-COMPONENT CARTRIDGE FILLING SYSTEMS

View More -

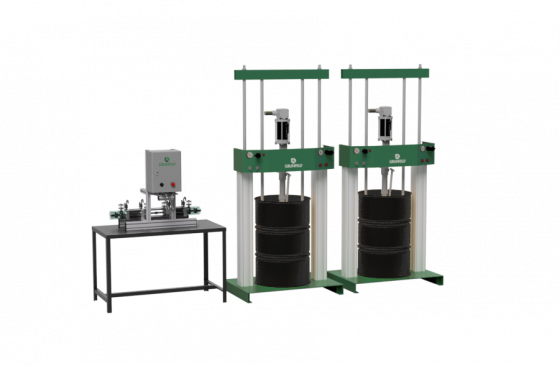

HYDRAULIC DISCHARGE PRESSES FOR MIXING VESSELS

View More -

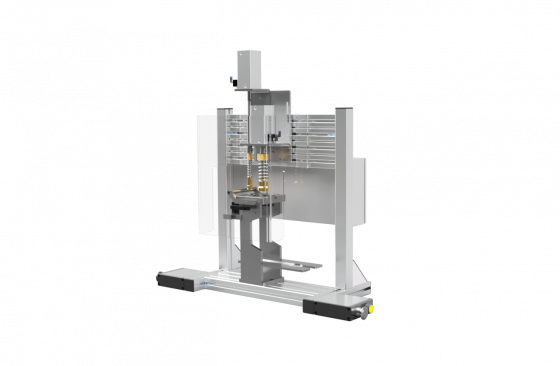

SEMI-AUTOMATED 2-COMPONENT CARTRIDGE FILLING SYSTEM BENCH-TOP

View More -

SEMI-AUTOMATIC PISTON INSERTION

View More