Filling & PACKAGING SYSTEMS

FOR LIQUIDS & PASTES.

Grunfeld specialises in designing and manufacturing systems for filling and packaging liquids and pastes into – Cartridges, Tubes, Pots, Bottles, Chubs, Pails, and Drums.

Grunfeld specialises in designing and manufacturing systems for filling and packaging liquids and pastes into – Cartridges, Tubes, Pots, Bottles, Chubs, Pails, and Drums.

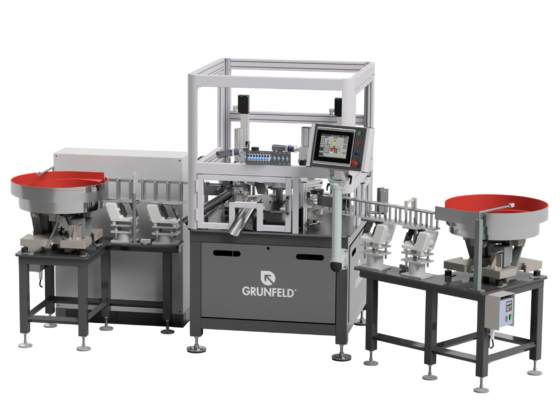

The range includes systems to fill cartridges in a vertical orientation, and a horizontally orientation, along with a range of Presses (for Drums or Mixing Vessels) to feed the Filling Systems

The range includes Semi-automatic Filling and Piston Insertion Systems, and Automatic Filling Systems. Along with a range of Presses (for Drums or Mixing Vessels) to feed the Filling Systems.

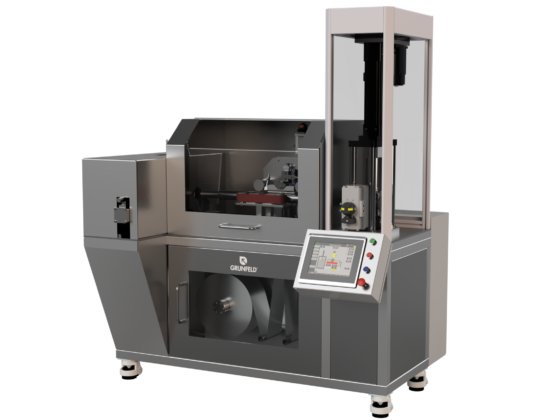

The range includes Hydraulic Discharge Presses for 200 litre (55 Gallon) Drums, and Customised/Bespoke Hydraulic Discharge Presses for Mixing Vessels

The range includes Automatic Bottle Filling (with a range of dosing technologies available to suit the requirements), Bottle Capping (for regular caps or more complex closures), and option for further downstream processes.

The range includes Tube Filling System for Plastic, Laminate and Aluminium Tubes, with automatic infeed of empty tubes, orientation, filling, and sealing, along with options for further downstream processes.

The range includes Semi-automatic Filling Systems, and Automatic Filling Systems (with option for further downstream processes). Along with a range of Presses (for Drums or Mixing Vessels) to feed the Filling Systems.

The range includes Automatic Foilpack/Chub Filling (Form, Fill and Seal) systems in horizontal configurations, along with a range of Presses (for Drums or Mixing Vessels) to feed the Filling Systems

The range includes systems that fill by weight (for lower viscosity products) and systems that fill by volume (for high viscosity products), along with a range of Presses to feed the Filling Systems

Dispensing Systems for a wide range of applications – Moulding & Casting, Panel Lamination, Gluing & Bonding, Sealing & Gasket, Potting & Encapsulation, and Fluid Transfer.

Posted

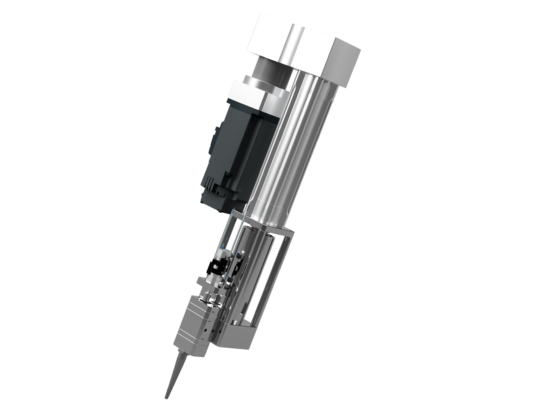

Understanding Servo Dosing Systems: Advantages, Configurations, and Alternatives

Servo dosing is a term we use frequently, and for good reason. Put simply, servo dosing refers to a system where the dosing piston is driven by a linear actuator, which in turn is powered by a servo motor. This approach offers high levels of precision, repeatability, and control—key requirements in modern automated filling systems.

Posted

Recently, a customer visited us and saw an automated cartridge-filling machine being built.

Posted

Rear Filling vs. Front Filling for 2-Component Cartridges

When it comes to semi-automatic filling of 2-component cartridges, there are two commonly used methods: rear filling and front filling. Each approach has its own advantages, limitations, and best-use cases.

Posted

Futureproofing Your Filling Line Investment

When investing in a new filling line—or upgrading components of an existing one—futureproofing should be a key consideration.