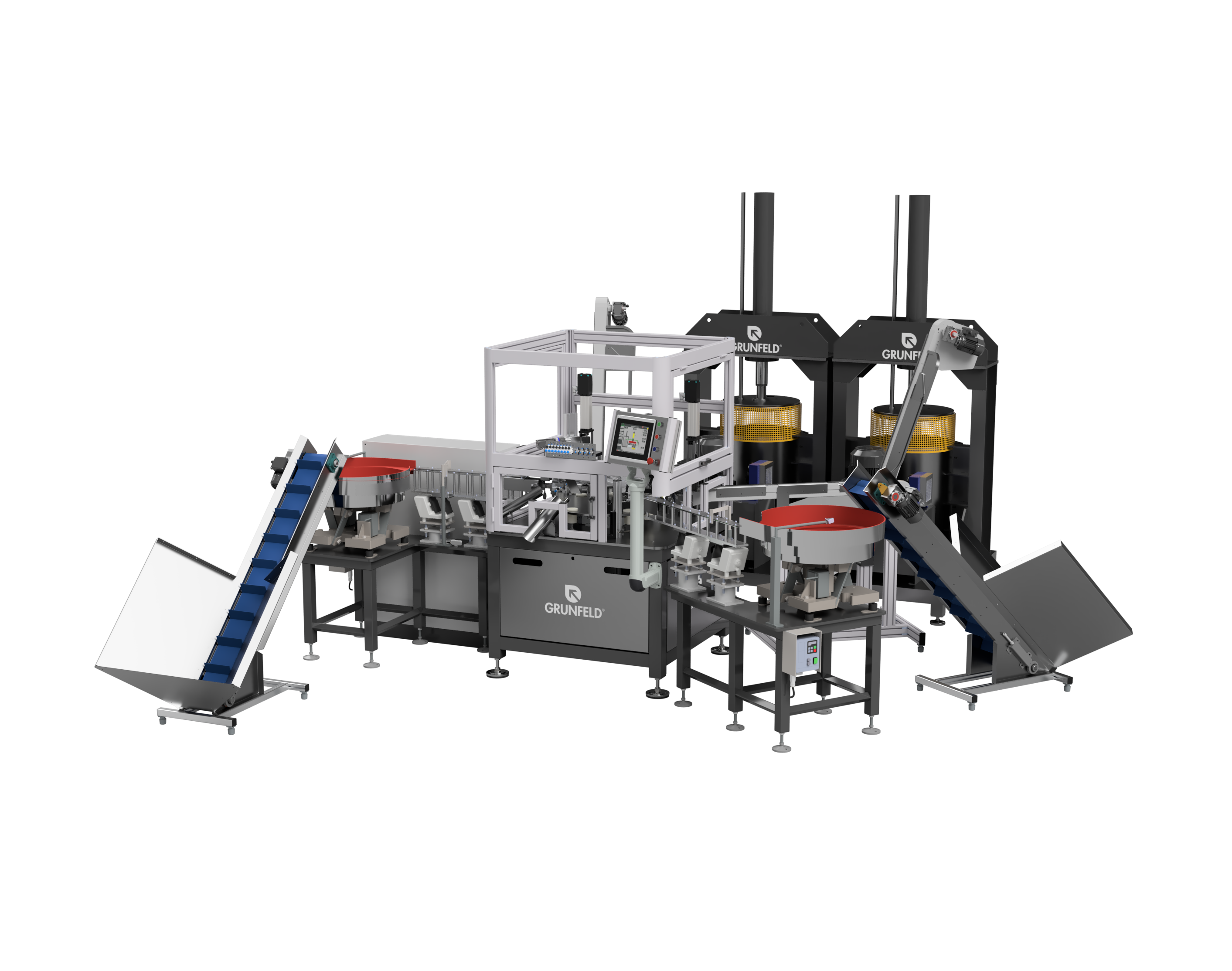

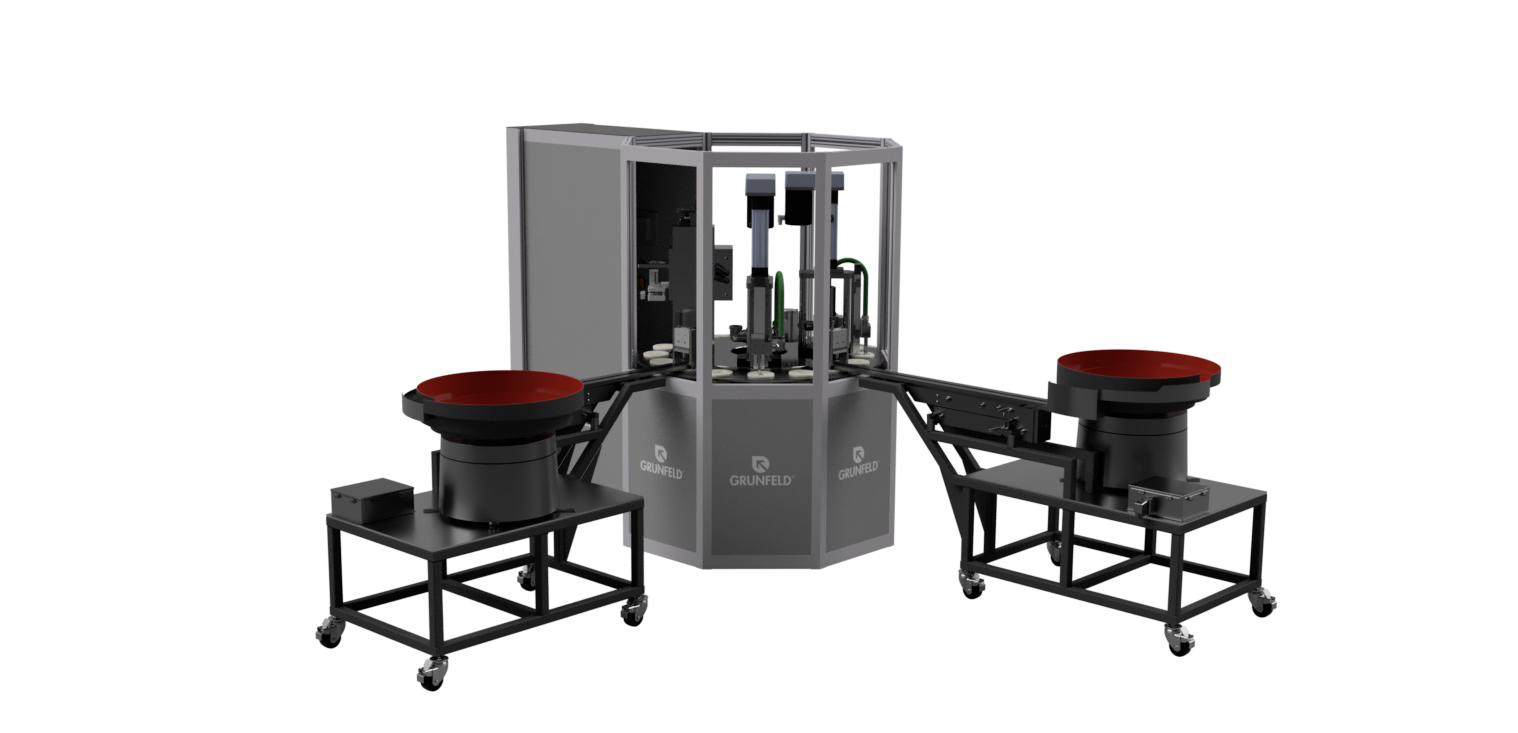

AUTOMATED 2-COMPONENT CARTRIDGE FILLING SYSTEMS

The GF-A Range of filling systems are designed for high speed fully automated packaging of 2-component adhesives, casting resins and sealants where rigid plastic twin cartridges are utilised.

The complete operation from the sorting, aligning, feeding, picking & placing of cartridge bodies; precision filling of resin and hardener components; sorting, picking, placing and insertion of pistons; automated inspection & inkjet coding is carried out with maximum efficiency with no operator involvement.

Additional operations such as Hot Foil Sealing, labelling and flow wrapping can be added or integrated with our filling systems.

Available in two standard configurations –

FRP – Fixed Ratio/Pack Size (e.g. 1:1, 50ml)

MRP – Multiple Ratio/Pack Size (with all change parts designed for rapid switching between pack sizes)

All wettable parts and seal specification will be selected specific to your formulated chemistry. Mostly, wettable parts are machined from various stainless-steel grades selected for their particular properties.

CLICK HERE TO ENQUIRE

HAVE A QUESTION?

Give us a call on +44 (0) 1626 912260

Available Monday - Friday, 9am - 5pm