Whether you need to supply adhesive to your high speed automated dispense line or to supply adhesive resin and hardener components to cartridge filling lines, reliable drum pumps are of key importance.

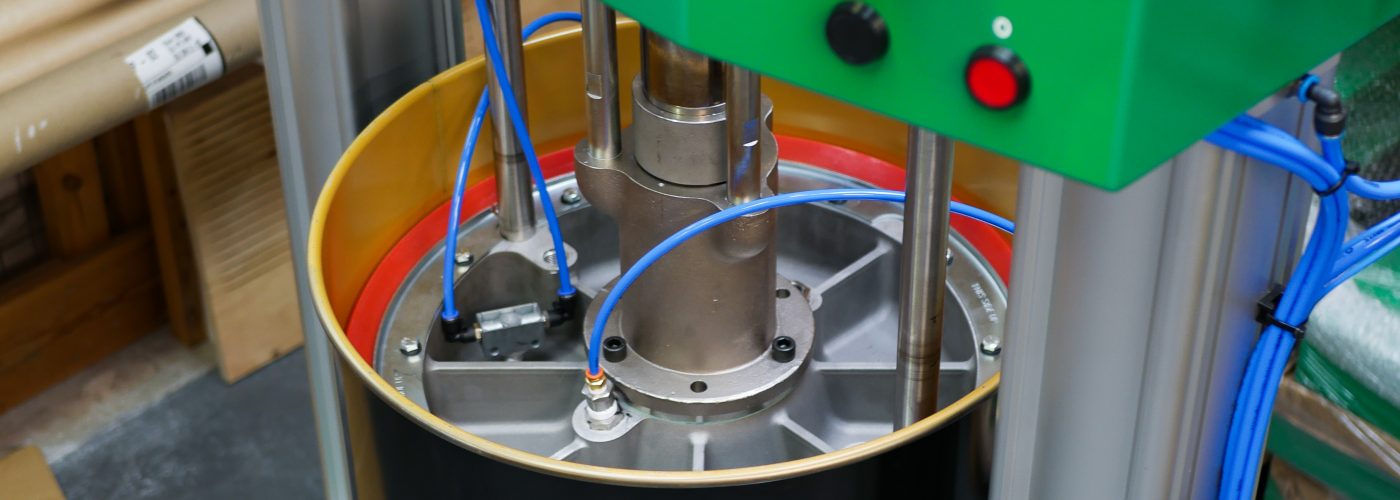

Large range of pump and air motor combinations, i.e. ratios from 1:1 up to 100:1, flow rates of up to 124 LPM.

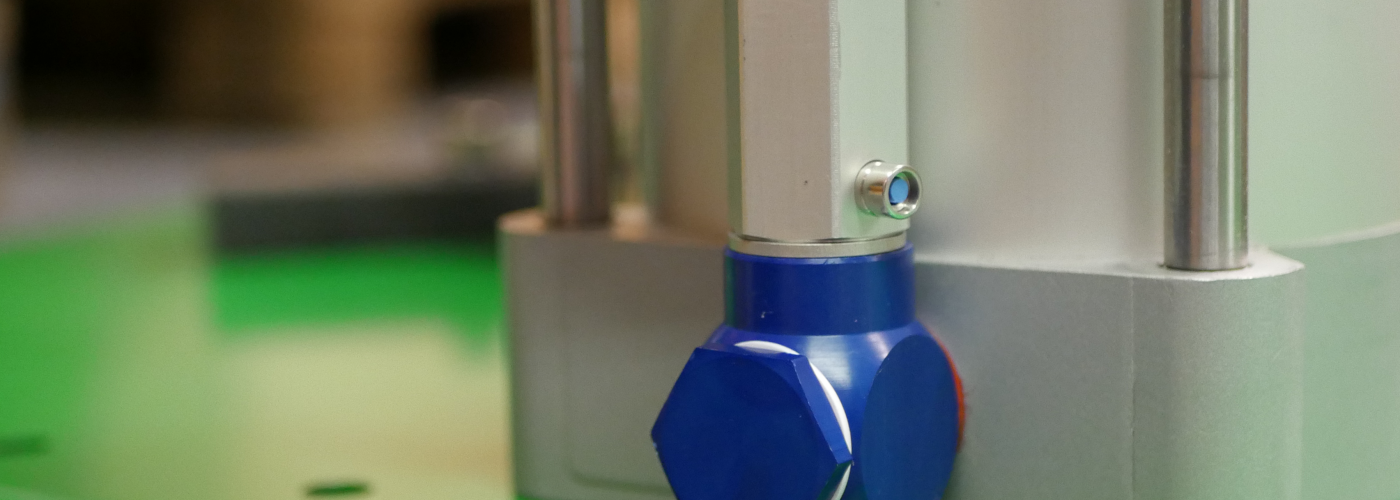

Chop Check, 2-Ball and 4-Ball Pumps depending on material properties, i.e. viscosity and rheology.

Material options for pump lowers to ensure chemical compatibility, including ceramic hard coating for abrasive materials, different stainless grades for chemical compatibility. Best material match specs. for Epoxy, Urethane, Acrylic, Methacrylate, Silicone and Polysulfide.

Different follower plate configurations with full PTFE Coated variants available, for both 20L and 200L drum sizes, custom options available.

Single and twin-post lift options.

ATEX Variants available