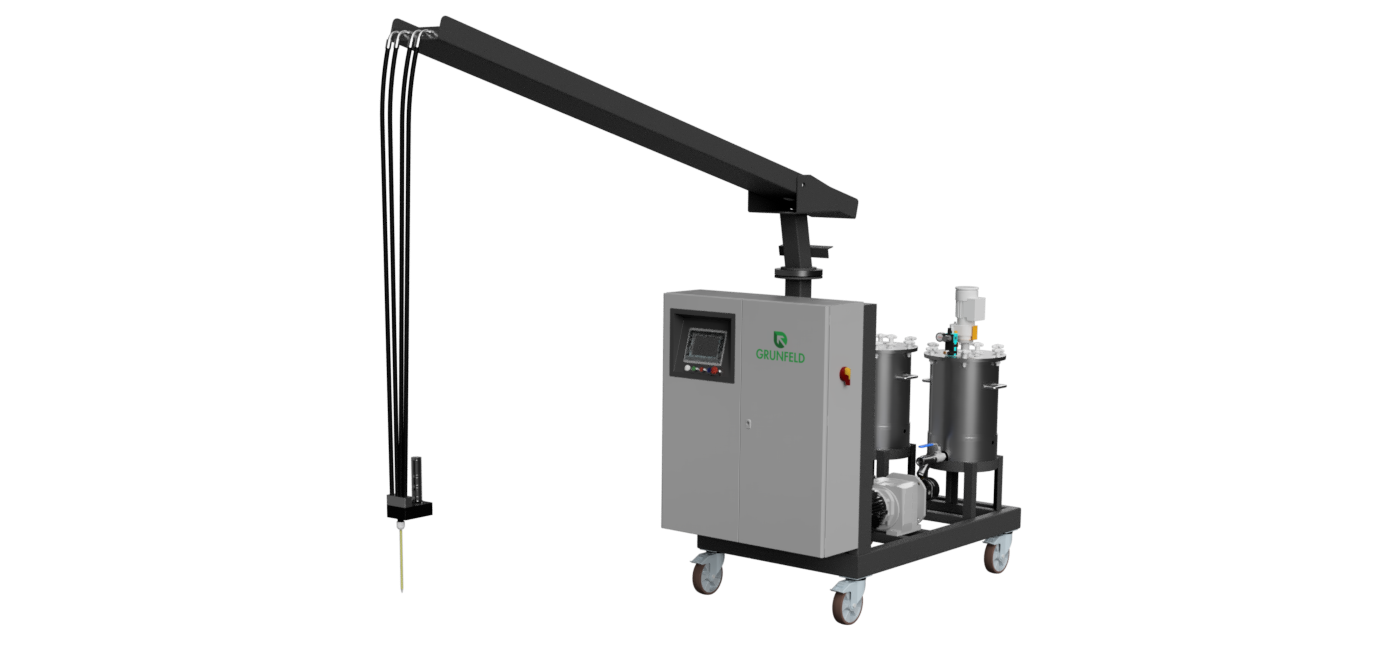

REACTION INJECTION MOULDING SYSTEMS

Grunfeld Reaction Injection Moulding Systems; for the dispense of two-component RIM Resins.

- Available in various output sizes (litres per minute) to suit mould sizes and injection methods.

- All Isocyanate pumps are tripled sealed with barrier fluid chambers to prolong seal life.

- Option for Silicone Carbide Wear Parts to increase service life where abrasive fiber-filled resin are used

- Mix ratio is changed with the touch of a button on the HMI touch screen. To change dispense speed/output the operator can choose between pre-sets or dial-up a speed of their choice – all on the touch screen – the program automatically calculates and maintains the correct ratio regardless of speed selected.

- PTFE core high-pressure hoses keep moisture away from the Isocyanate and remove the risk of crystallization or curing in the lines.

For more information on specifics, models, and variants or to discuss your requirement please contact us.

download – Grunfeld Reaction Injection Moulding brochure

CLICK HERE TO ENQUIRE

HAVE A QUESTION?

Give us a call on +44 (0) 1626 912260

Available Monday - Friday, 9am - 5pm