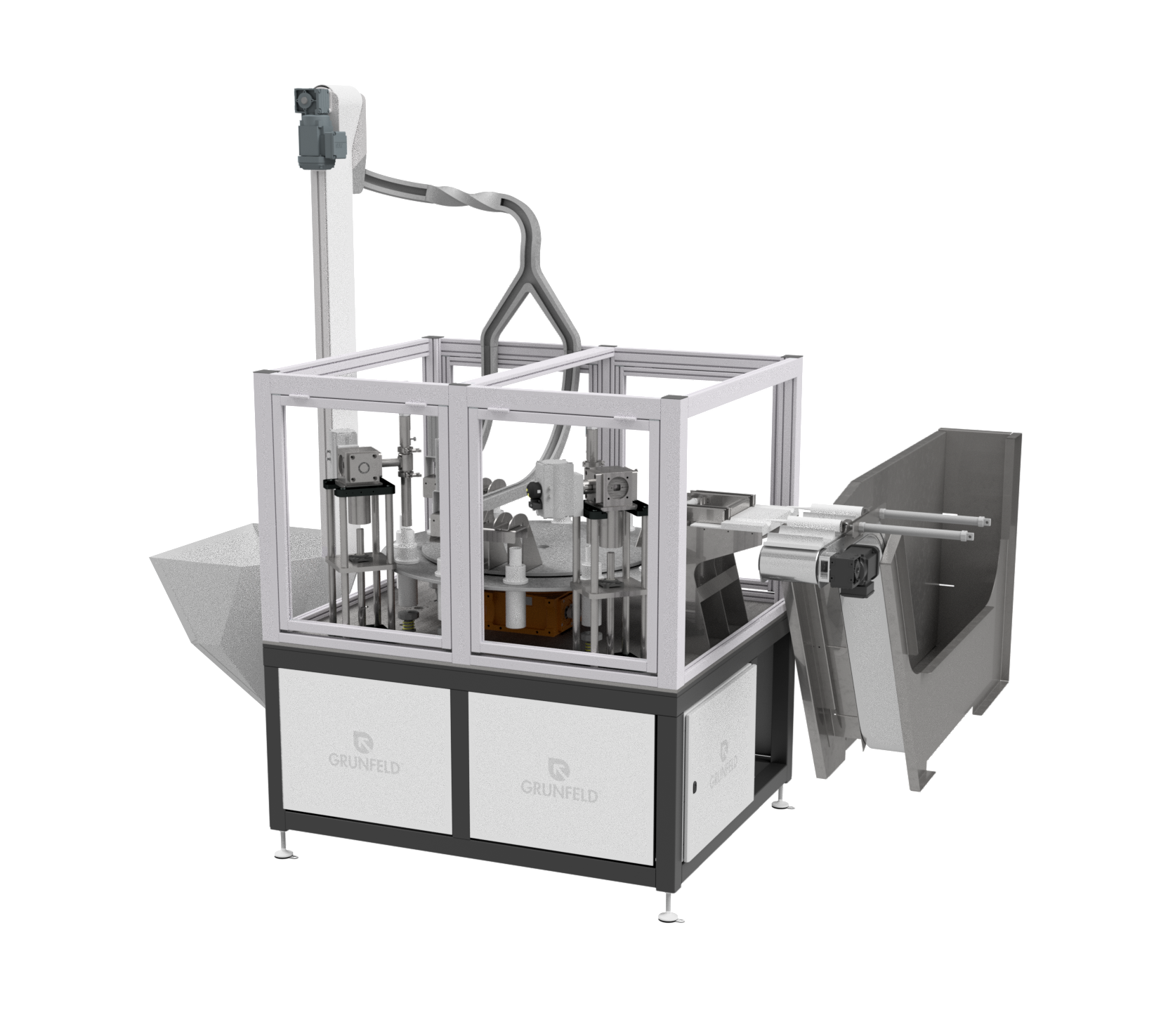

AUTOMATED VERTICAL CARTRIDGE FILLING SYSTEM

Bulk quantities of cartridges are loaded into the bulk hopper and are elevated to the loading station, which places them onto the indexing table.

The Rotary Table indexes and transports the cartridges through the Processes.

High-duty and accurate dosing units deliver the sealant into the cartridges. Available in single and twin-head configurations – to deliver the required throughput.

The complete fluid contacting parts assemblies are quickly and easily removed for cleaning off-line.

Bulk quantities of Pistons are loaded into the Piston hopper, from where they are elevated and sorted, and fed to the insertion station.

An additional station is available for any product-specific processes required.

The finished cartridges exit through the outfeed chute, onto the outfeed conveyor, ready for downstream operations.

Additional end-off-line options available; clip-nozzle attachment, case packing, and palletizing.

HAVE A QUESTION?

Give us a call on +44 (0) 1626 912260

Available Monday - Friday, 9am - 5pm