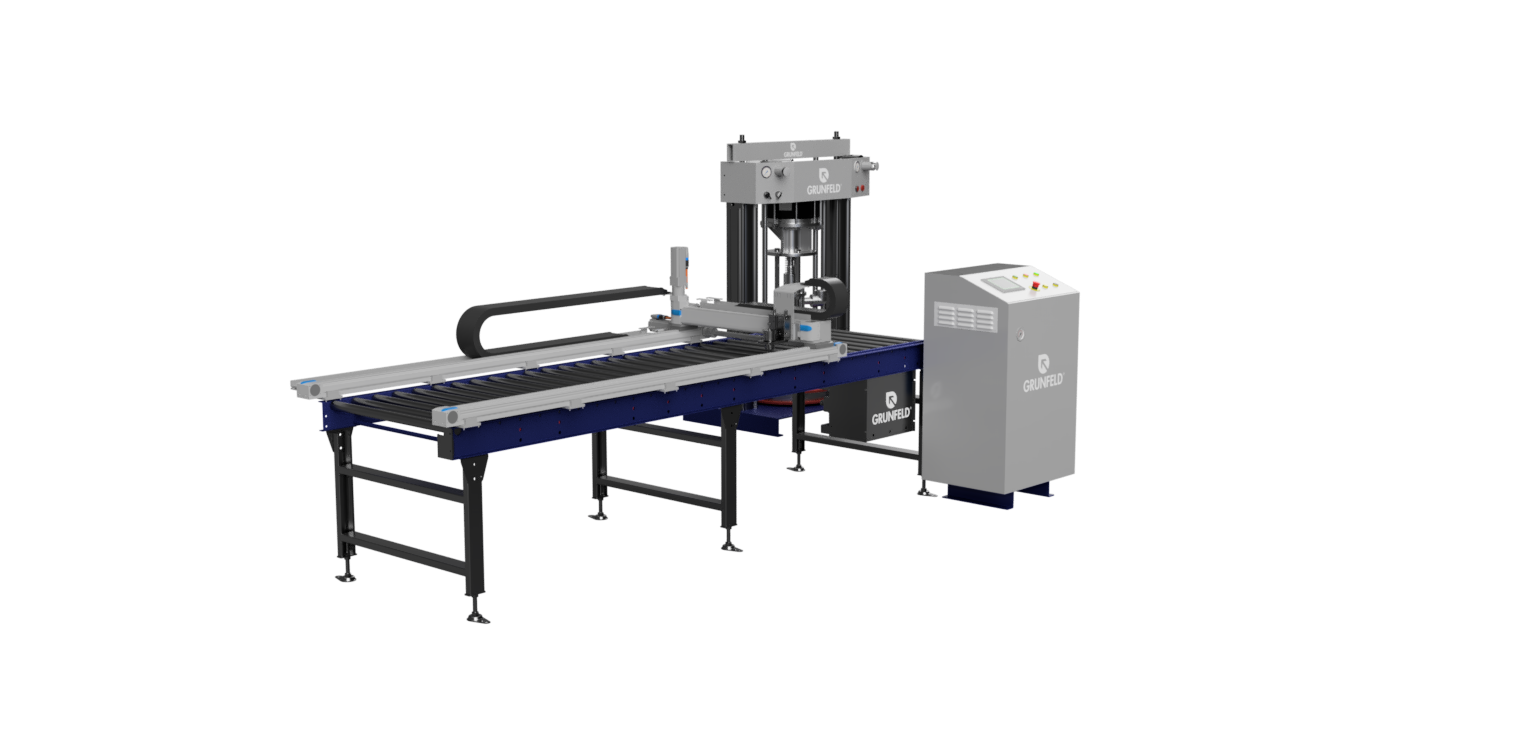

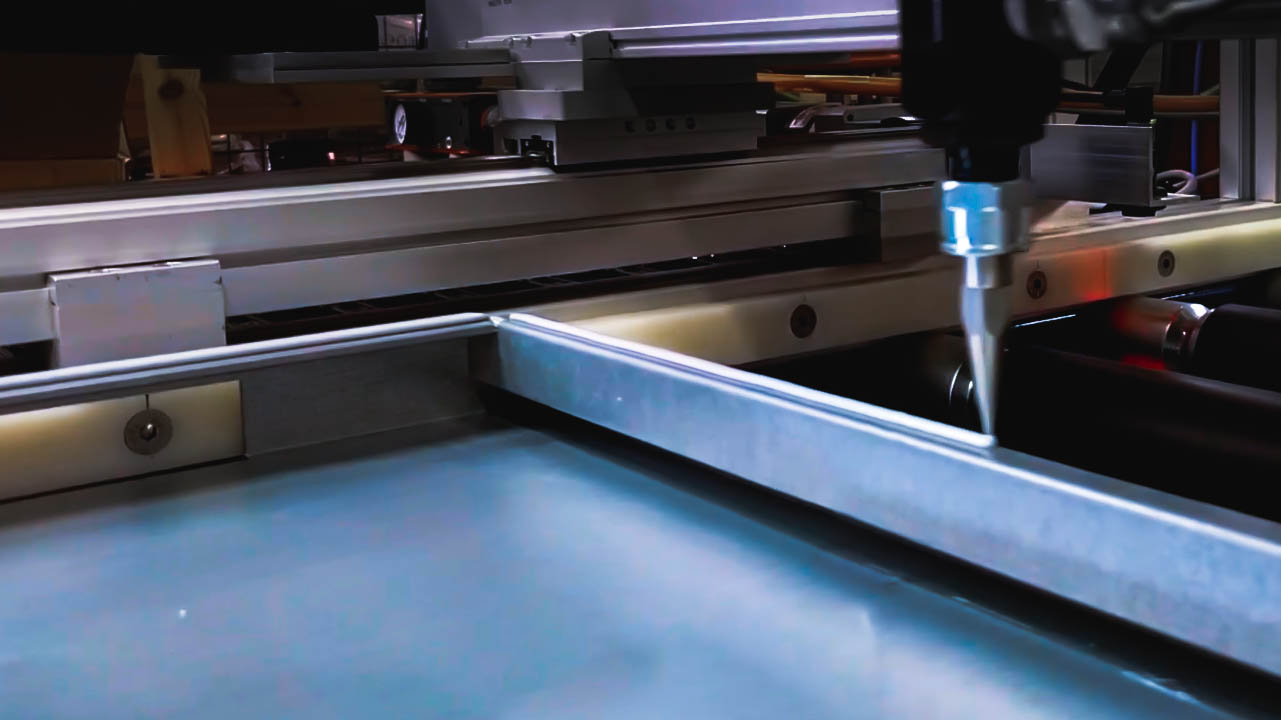

Automated Adhesive Dispense Systems

“Automated Dispense Systems for flat and 3D panel laminations, bonding SIPs, composite panels – X-Y Axis gluing lines and full robotic applications.”

There can be many reasons for considering the automation of a bonding process.

When implemented successfully, the outcomes are always the same – better product, faster throughput, reduced waste and reduced cost.

How many times is a constraint discovered because a particular manufacturing process “can’t be done by just anyone”!?

How many times do bonded parts fail, because the operator applied the adhesive, went for a break and ‘got diverted’ on his return, assembling the parts some 15 minutes later than they should have been?

How many times has your production throughput been determined by the number of good operators that can correctly apply the adhesive or sealant?

How often do you wish that you could save time in your production process?

How much time is spent training and re-training production operators when a process failure results in scrapped parts?

Don’t only think of robots! Many of us conjure up in our minds, visions of bright orange robots dancing above the body shells of cars, applying hem flange sealant at breath-taking speeds.

Whilst robotic systems have their place, there are often more appropriate systems of automation, that whilst not so fascinating to watch are fast, efficient and ultra-reliable.

The key objective is to improve the consistency of the finished product or sub assembly, to increase throughput and reduce costs.

CLICK HERE TO ENQUIRE

HAVE A QUESTION?

Give us a call on +44 (0) 1626 912260

Available Monday - Friday, 9am - 5pm