1-Component Cartridges are typically filled in large quantities, which in most cases justifies using automated filling equipment. Filling small quantities of 1-Component Cartridges can be done with simple equipment or even manually, so at Grunfeld we focus on Automatic 1-Component Cartridge Filling.

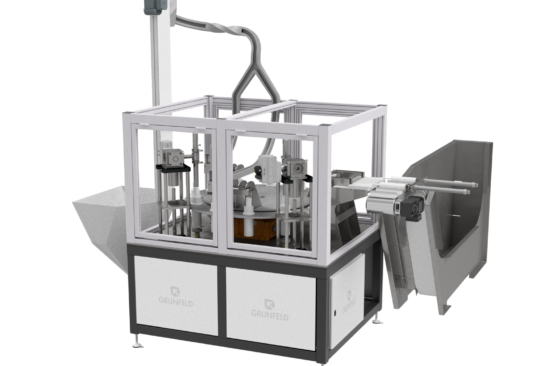

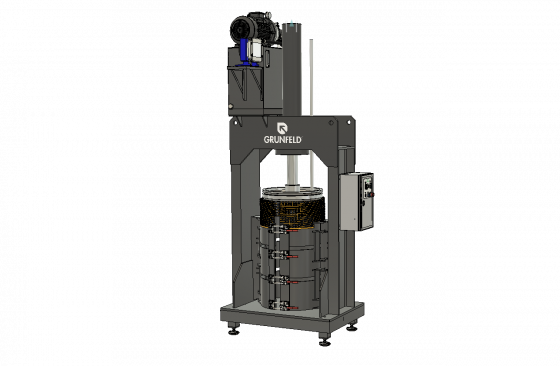

1-Component cartridges can be fed and processed vertically through a rotary carousel (typically suited to lower-viscosity materials) or horizontally through a walking bed (typically suited to higher-viscosity pastes).

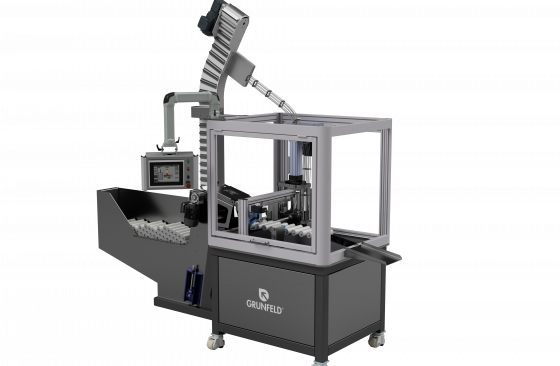

Bulk quantities of empty cartridges are loaded into the bulk hopper/magazine, where an elevator conveyor automatically transfers them up into the cartridge filling machine. The feeding of the empty cartridges, the filling of the cartridges, the sorting, feeding, and insertion of the pistons, are all completed autonomously.

With options for inkjet coding, automatic sorting, feed and attachment of clip-on-nozzles, and other end-offline processes.

Some of the key considerations that influence a machine specification are: The viscosity of the material to be filled into the cartridges, the duty cycles and required outputs (piece per minute), and Chemical compatibility with the fluid contact (wettable) parts of the machine.

Often the Materials filled into 1-Component Cartridges are moisture curing, so all fluid contact (wettable) parts of the machines are designed for quick disassembly and easy cleaning.