Moving Glue Head ‘vs’ Moving Substrate

Posted

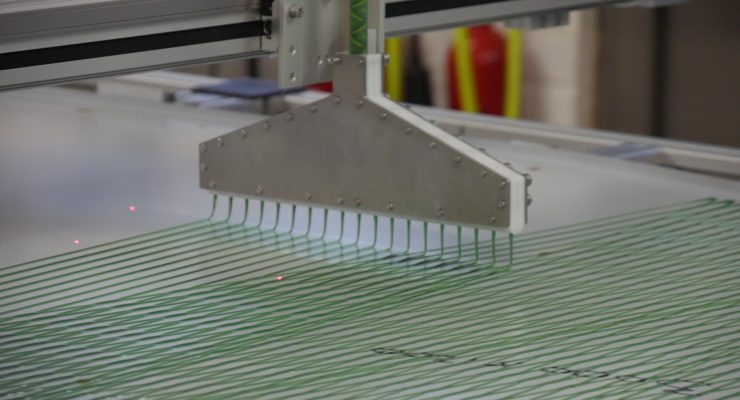

Some adhesive dispensing systems have a moving glue head, where the glue head moves over a stationary substrate.

Some have a stationary Glue Head that the substrate passes under.

And some have a combination of both.

Benefits of a ‘moving glue head’

- The entire footprint of the equipment can be a similar size to the substrate (or the largest substrate the system needs to handle), resulting in a minimal footprint, which is a good thing, it doesn’t take up as much floor space.

- Typically, the glue head is lighter than the substrate, so less inertia in a moving glue head, a benefit when having to change directions, or follow contours and apply in un-uniform areas on a substrate.

Limitations of ‘moving glue head’

- With high viscosity adhesive and an application over a large area, the frictional loss of pushing thick adhesive through a long hose will reduce the output and therefore dispense speed.

Benefits of ‘moving substrate’

- While the ‘moving glue head’ is limited by a combination of high viscosity adhesive and long hose, ‘moving substrate’ scores here, because the static head can be located close to the dispensing/pump equipment, minimising the hose length and resulting frictional loss (to read more about frictional loss in hoses click here)

- Often the adhesive application is a step in a large process, with the material/assemblies to be glued coming from and moving on to other processes, so infeed and outfeed conveyor are needed for the general material follow anyway.

Limitations of ‘moving substrate’

- Because the substrate must pass under a static head the footprint of the equipment (in most cases) needs to be at least double the length of the substrate; so it can feed in and out from under the head. If space is limited a ‘moving glue head’ offers a more compact solution.

Combination of ‘moving glue head’ and ‘moving substrate’ – for applications where substrates are fed into the glue application area, components and substrates are added in the glue application area, and the substrate is then fed out of the glue application area, a combination of ‘moving glue head’ and ‘moving substrate’ can offer great versatility, reduce application time, and reduce product handling.

There are various other considerations to be made, which we can hopefully cover in further blogs, but for now please feel free to get in touch with us to further discuss your application.