Have you thought about automating the visual inspection conducted on your production line?

Posted

Machine vision systems have the ability to capture and evaluate targets in two dimensions, making them very useful for automating inspections once done by the human eye.

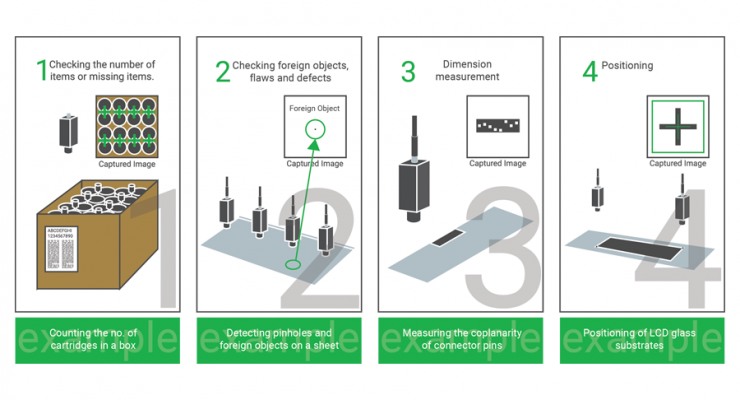

Most industrial inspections fall into one or more of the four major machine vision applications.

There are four major machine vision applications. Most machine vision applications in various industries can be categorised into the four groups illustrated.

Advanced vision systems can be incorporated into your automated dispense system and can identify and verify that adhesive has been applied in the right area, can measure and verify bead sizes, can verify the correct application of primers and activators where photo-fluorescent dyes are added for inspection regimes. Alignments can be verified where pick and place options are specified after gluing application. The possibilities are extensive, giving the manufacturing entity assurance that their processes are correct in critical applications.

One major benefit offered is that parts incorrectly manufactured are automatically identified and rejected, ensuring the consistency of your product.