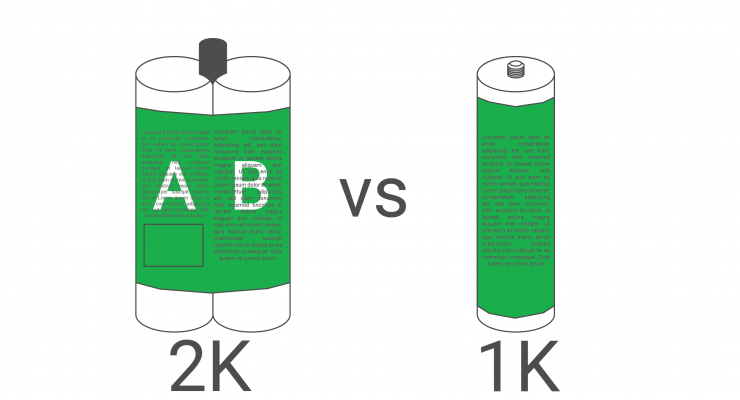

Application Matters: Chemical Curing Adhesives. 2K versus 1K.

Posted

There are many different chemically curing adhesive chemistries available on the market. However, knowing which adhesive is the right one for your application can be tricky! Chemically curing adhesives mostly fall into one of two categories. 1 component adhesives and 2 component adhesives. Both have benefits and disadvantages. The key is to get the right product for your application.

In this blog we will briefly cover the main types of chemically curing adhesives available and discuss how they need to be handled and dispensed correctly.

Single Component adhesives

Single Component adhesives require specific conditions to start the curing process, this can be heat, light, humidity or oxygen to name a few, until these conditions are met the adhesive will not bond. Therefore, the packaging, processing and dispensing of these adhesives must be carefully chosen to ensure that the adhesive does not start to cure before it reaches its destination.

There are 6 major classes of single component adhesives. Anaerobic, Cyanoacrylates, Heat Cure, Moisture Cure, Radiation Cure and Silicones and each must be handled and processed in accordance with this.

Anaerobic adhesives cure in the absence of oxygen. Oxygen stops the curing reaction from happening, so for this type of adhesive oxygen must be present until the adhesive reaches the bond site. Anaerobic adhesives are often used in thermosetting applications and the resulting bonds are high strength and have high heat resistance, but also tend to be brittle.

Cyanoacrylates have “instant bond” they have a wide range of industrial uses and also are well known in domestic circles as “superglue”. Cyanoacrylates are popular for bonding a wide range of materials including, glass, metal and most plastics. The way that cyanoacrylates are applied is very important due to their cure speeds.

Heat cure adhesives require high temperatures to cure, this results in a cured product that is very high strength, heat resistant with good chemical resistance. There are 3 common types of heat curing adhesives each with their own unique properties. Epoxy resin-based heat curing adhesives are probably the most common and are widely used in the automotive, aerospace and metal fabrication industries. Cured epoxies are hard and rigid but tough with excellent chemical and heat resistant properties. Phenol-formaldehide (Phenolic) resin-based heat curing adhesives are generally used in wood structures that require resistance to water and weathering. Polyimide is another common type of heat curing adhesive. Bonds created are normally tough and hard with high strength but still remain elastic. Polyimide heat curing adhesive is used extensively in the automotive industry.

Moisture curing adhesives are typically viscous and require moisture to start the curing reaction. This broad group comprises Polyurethane, Silicone and Silane Terminated Polyether Polymers. These polymers are largely non-volatile so are safer for operators and the environment requiring little or no hazard classification. Cured adhesives can range from rigid and hard, to flexible and soft depending on the adhesive composition. Moisture curing adhesives are used extensively across many industries where their flexibility and low VOC (volatile organic compound) is valued. Application of moisture curing adhesives is critical as any exposure to moisture will start the curing process. It is essential to ensure that when packaging and applying these adhesives, the correct equipment is used to prevent moisture ingress.

Radiation cure adhesives require light at a certain wavelength to cure, and do not normally cure until exposed to the correct wavelength for the needed period of time. At least one of the substrates must be permeable to the light in order for the cure to take place. Radiation cure adhesives are commonly used in glass bonding applications. They are also being used increasingly in dental applications.